In 2024, we completed our role in one of the most significant remediation and rehabilitation projects in Newcastle's history.

Since the early 2000s, we have worked on behalf of the NSW Government to remediate and rehabilitate two former BHP Steelworks sites around the Port of Newcastle – including a former steelworks site at Mayfield, and its associated landfill facility at Kooragang Island.

The 'steel city' legacy

BHP's Steelworks operations played a pivotal role in Newcastle's economic development for almost a century – however – it also made a notable and unfortunate impact on the local environment.

The steel and copper smelting works were energy intensive and produced a large volume of solid liquid and vaporous wastes. Contaminants had seeped into the soil and groundwater, leading to widespread environmental degradation.

The remediation of these sites marks a major milestone in Newcastle's evolution from 'steel city' to a modern, diverse and vibrant regional economy.

We have delivered significant works and infrastructure to contain and manage contaminants, mitigate significant environmental hazard, and enhance the lands for new use.

The strategic works have protected the surrounding environment and improved and safeguarded the local flora and fauna for future generations.

The once unusable lands have now been converted into valuable portside assets – providing new opportunities for site reuse and employment generation.

The remediation project

Mayfield

The rehabilitation of BHP's 152-hectare former steelworks site is one of the biggest and most important remediation projects in Newcastle’s history.

The main operational area of the former BHP Steelworks operation sustained severe impacts to soil and groundwater over its 84-year lifespan. The $110-million project involved a complex range of works to contain or remove contaminants, and return the land to a productive state.

|

|

The world's deepest underground barrier wall – a pioneering achievement.

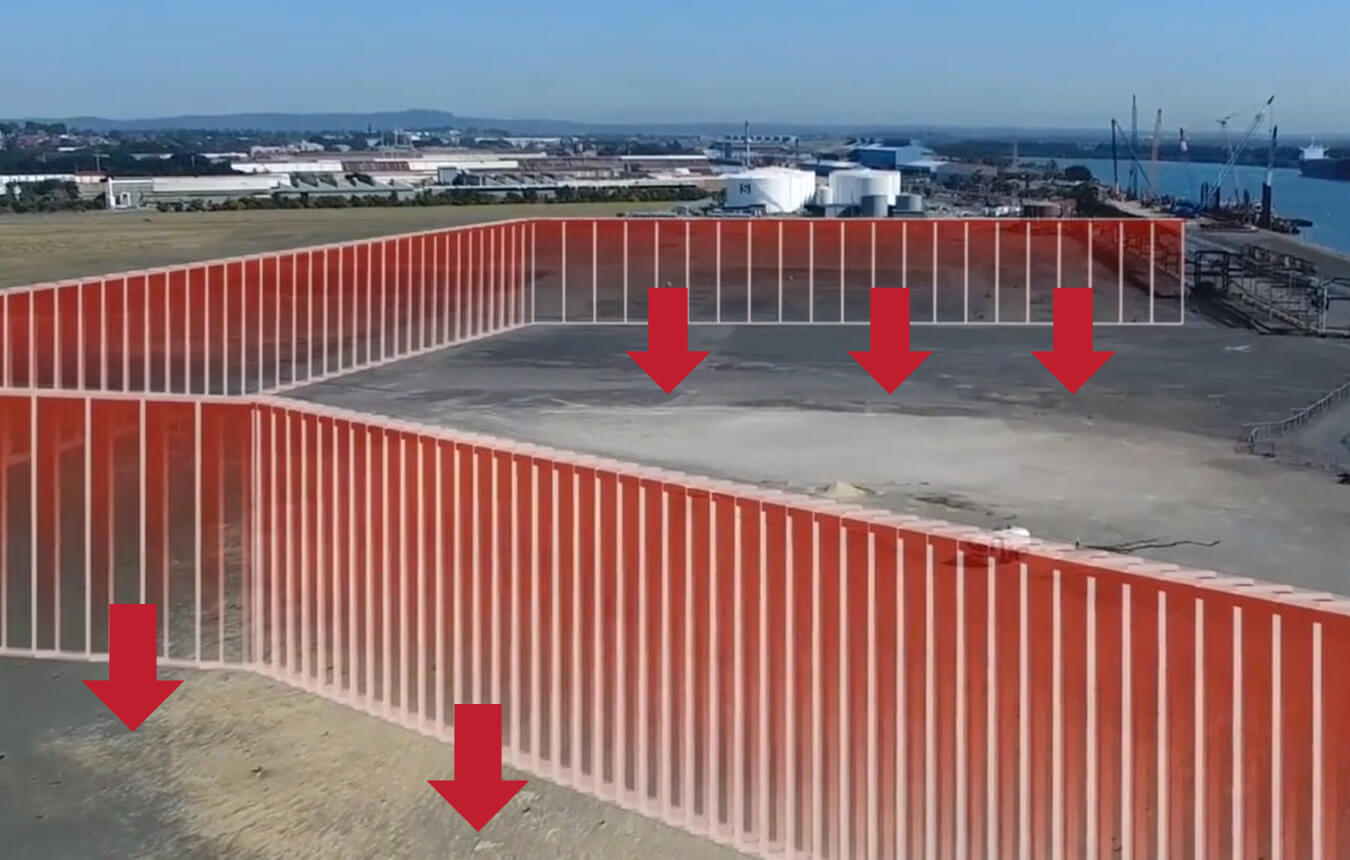

The Mayfield remediation project included a 50m deep x 1.4km long underground ‘barrier wall’ including surface capping and major stormwater drainage features to prevent contaminated groundwater from spreading towards the Hunter River.

Mayfield's remediation works were acknowledged with a NSW Premier’s Award in 2016 for protecting the environment, and works were formally completed in 2019.

Kooragang Island

For decades, the 65-hectare Kooragang Island site served as a landfill waste facility for Mayfield Steelworks, becoming contaminated and posing a risk to the Hunter River and surrounding environment.

Our remediation focused on an efficient capping strategy including major civil works. We collaborated with a specialist team of scientists and engineers to solve the complex challenges of the site and develop innovative strategies for repairing the lands and enhancing the surrounding environment.

|

|

We undertook proactive initiatives to promote future use of the site, including works to improve load-bearing capacity, prevent contamination and mitigate flooding. We also sourced reuse materials to reduce quarry costs, and identified materials that create water conditions favoured by local wildlife.

The complex remediation works completed in 2022 are recognised with high accolades including a Civil Contractors Federation of NSW 'Earth Award' for Daracon Group's work as the project's head contractor.

Ecological solutions

Kooragang Island is an environmentally sensitive site situated near the Hunter Estuary Wetlands, and home to the a variety of wildlife including the protected Green and Golden Bell Frog.

We worked closely with ecology specialists to restore the sites native vegetation, create new wetlands and provide a healthy habitat that has become a refuge for frogs, insects and other native species.

|

|

Wetlands play a critical role in natural water purification and provide essential habitats for local wildlife including the protected green and golden bell frog.

The remediation works were designed sympathetically to the sites native environment and we introduced over 20 wetlands covering 8-hectares.

|

|

The wetlands were constructed with a balance of soil, rock and new vegetation to redirect surface water flow, and provide a healthy habitat for protecting the sites endangered frogs.

Revegetating the land during and after remediation was a carefully considered process.

Substrates and hydrology were designed to generate a mix of vegetation that is sympathetic to existing flora and optimised for wildlife species.

|

|

The land regeneration and restoration included replanting the site with native grasses germinated from locally harvested seeds to provide optimum ecological and sustainability outcomes.

Seeds from nearby lands were collected and stored prior to commencing remediation – and then later distributed across the site, creating a diverse native flora cover just months after earthworks were complete.

At every stage, the works were designed to protect and provide a healthy habitat for the endangered Green and Golden Bell Frogs (Litoria aurea) that inhabit Kooragang Island.

We worked with the University of Newcastle's wildlife ecologists to create innovative 'frog-friendly' solutions and provide a healthy environment for foraging and breeding.

|

|

A unique exclusion fence was installed to protect the frogs during construction, featuring an automated irrigation system and a series of mini refuge ponds to keep the frogs safe, hydrated and sheltered around the project perimeter.

Contaminated waste was separated from potential habitats, delicate water balances were maintained to support the species, and frog breeding habitats were introduced providing a working model for future habitat projects.

Economic benefits

The sites have now been unlocked for a range of economic opportunities and have already boosted the local economy by facilitating billions of dollars in investment – with much more to come.

|

Operations already utilising the Mayfield site include a cargo storage facility, rail infrastructure, a bulk liquids fuel facility and the Hunter River remediation project.

Remaining lands on the Mayfield site have been earmarked for a deepwater container terminal, which Port of Newcastle estimates will bring $2.5 billion to the local economy and generate 19,000 jobs.

Plans are underway for Kooragang Island land to become part of a new Clean Energy Precinct, which could generate up to 5,800 jobs and position Newcastle as a leader in producing, storing and exporting clean energy materials.

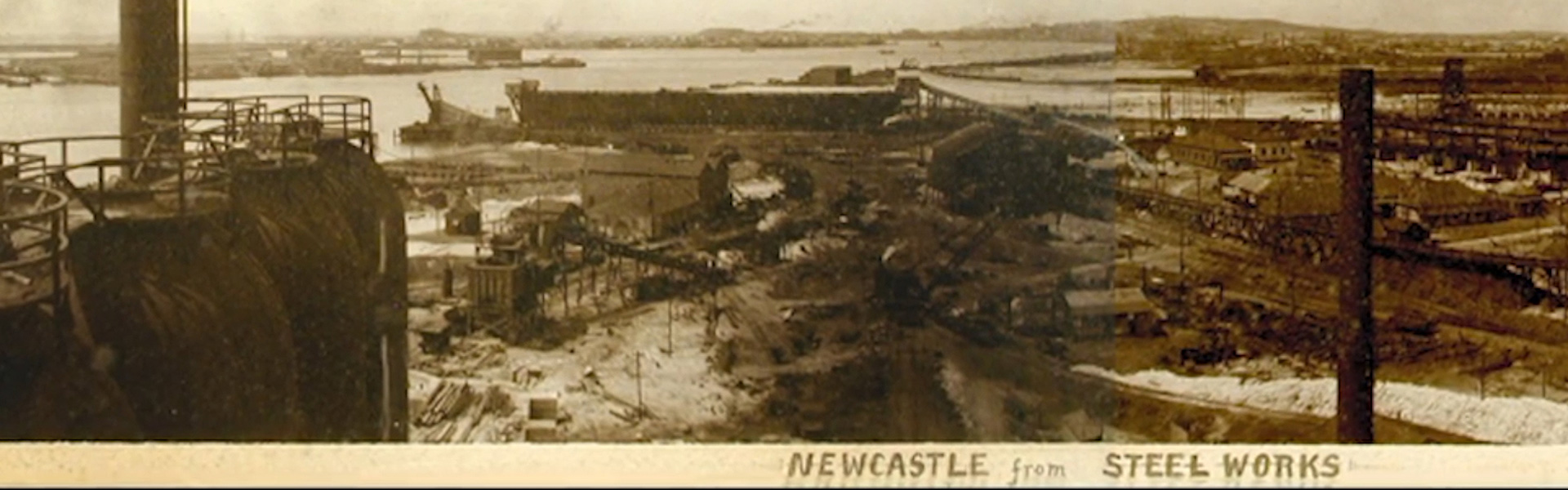

Founded on one of Australia’s oldest industrial sites, BHP's Newcastle Steelworks was vital to the regional and national economies during its 84 years of operation from 1915 to 1999. In addition to the 152 ha steelworks site, BHP also operated a 65 ha landfill site on the nearby Kooragang Island.

The Steelworks operations employed thousands of people and produced millions of tonnes of steel each year for distribution around Australia and overseas.

Steel production was a cornerstone of the social and economic fabric of Newcastle for more than 80 years, earning the ‘Steel City’ nickname. Combined with the coal industry, steelmaking formed the lifeblood of Newcastle and the Hunter regional economy.

Legacy environmental impacts

Prior to BHP's Newcastle Steelworks operations, the Mayfied land was used as a Copper smelter, commencing circa 1870. The legacy of extensive steel and copper smelting operations at these sites had a notable impact on the local environment. This long industrial history gave rise to contaminated soil and groundwater right across the site, leading to widespread environmental degradation.

In 1999, BHP permanently closed the main Newcastle Steelworks site. This marked a significant milestone in Newcastle’s history, resulting in thousands of job losses and impacts that reverberated through the local economy.

Following the steelworks' closure the land was transferred from BHP to the NSW Government for management of the land assets and remediation of the site in line with Environment Protection Authority (EPA) requirements.

The significant and complex remediation was delivered over numerous design and capital works stages spanning nearly two decades; returning the land to a suitable state for future reuse.

The remediated Mayfield site includes memorial artwork installations dedicated to those who worked at the former BHP Steelworks sites.

The first, called Muster Point, is a large steel art installation paying tribute to the steel-working skills of the BHP workers.

Another memorial installation was unveiled at the centenary of the plant’s official opening on 2 June 1915, paying tribute to those who lost their lives at the steelworks. The sculpture is a moving ‘’mourning circle’’ produced by Branxton artist and blacksmith Will Maguire.